Big Bag type bags are gaining increasing popularity in various industrial sectors due to their versatility and wide range of applications. These multifunctional container bags come in different sizes, allowing for precise customization to meet the specific requirements of each customer. Additionally, they can be equipped with various features such as a spout for easy filling or emptying, handles for convenient transport, and special covers to protect the contents from moisture or contamination.

Thanks to their well-thought-out design, Big Bags are not only easy to use but also ensure convenient storage and transport. Their ergonomic shape allows for optimal space utilization, which is crucial in warehouses with limited storage capacity. They can be quickly filled, stacked in a space-saving manner, and safely transported to their destination. They are designed for easy loading onto different types of transport, minimizing the risk of product damage during movement. Their durability and reusability contribute to increased operational efficiency and cost reduction. With resistance to weather conditions and mechanical damage, Big Bags provide an economical solution for many industrial sectors.

Big Bag container bags also offer an environmentally friendly solution by reducing the need for single-use packaging. As a result, they are widely used in various industries, including construction, agriculture, as well as the chemical and food industries.

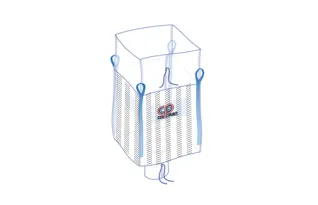

Standard Big Bags

Maximum utilization of space and load stability

Quick and convenient emptying thanks to the discharge spout

Maximum tightness and convenient transport

Precise loading and unloading control

One-time emptying without quality loss

Fast emptying and safe storage

Large capacity and easy transport

Convenient filling and emptying with maximum tightness

Special Big Bags

Big Bags Made from Polypropylene Fabrics

Polypropylene fabrics, from which Big Bags are made, effectively protect their contents not only from external factors but also from the harmful effects of UV radiation. This ensures that light-sensitive materials can be stored without the risk of degradation.

Big Bags are produced using various suspension constructions, such as single, double, and four-loop lifting systems. This variety allows the bags to be adapted to the specific logistical and operational requirements of each client. Thanks to the use of high-quality materials and well-thought-out design, these bags can be intended for single-use (SF 5:1) or multiple-use (SF 6:1). The outer surfaces of the bags often feature prints (e.g., company logos or warehouse markings) that facilitate identification and inventory management.

When designing Big Bags, we pay special attention to several factors, such as the type of packed products, packaging methods, conditions during packaging, types of transport, and methods of emptying the bags at the destination.

Big Bag Container Bags Are Primarily Used For:

- Transport – particularly important for transporting hygroscopic substances, which easily absorb moisture, as well as dusty materials that can be difficult to control;

- Transporting hazardous substances – ideal for transporting chemicals, petroleum products, and other toxic or reactive materials;

- Storage and warehousing – effectively used for storing various materials (from raw materials, through semi-finished products, to finished goods).

We Also Offer Advanced Packaging Options:

- Packaging with an additional liner (LDPE foil or multilayer laminates) – it can be inserted loose, sewn, or glued inside the container. These liners significantly increase the barrier properties of the packaging, protecting the contents from contamination and external factors;

- Electrostatic packaging – designed for transporting materials that can generate electrical charges. These packages are equipped with grounding systems that allow safe discharge of accumulated electrical charges and prevent the risk of electrostatic discharges;

- Shape-stabilizing packaging – maintains the cubic shape of the Big Bag, even under heavy load.

The construction of Big Bags is strictly related to their application. CERPLAST offers custom technical solutions tailored to the specific needs of clients, taking into account the methods and conditions of use. Big Bag container bags are designed to ensure maximum cargo safety and ease of handling, storage, and transportation. All these factors are considered in the production of CERPLAST Big Bags.

Considering practical aspects and individual customer requirements, we offer packaging with different filling options: open-top with or without a flap, skirt, or filling spout. We also provide various discharging structures for Big Bags: flat or conical bottom, discharge spouts, skirt with closure, and discharge flap. If you have any questions about the possible structural solutions for Big Bags and their practical applications, our qualified and experienced specialists are here to provide advice. Feel free to contact us!

Big Bags can also be categorized based on the type and number of lifting loops, which have numerous practical applications across various industries. We offer our clients:

Single-Loop, One-Handle Big Bags

This type of Big Bag container bag is commonly used in the chemical and fertilizer industries. These large-format packages provide a simple, cost-effective option while maintaining high durability and safety standards for stored cargo. Single-loop Big Bags are made from high-quality materials that are highly resistant to tearing. The structure typically features an open top and a bottom designed as a nest, square, or single seam, depending on customer requirements.

Two-Loop, Two-Handle Big Bags

This type of Big Bag is similar in construction to the single-loop variant. It is also made from extremely durable materials that are resistant to tearing. As the name suggests, the only structural difference lies in the presence of two handles. These bags are commonly used for storing lime and fertilizers. Depending on customer requirements, the bottom can be designed in the shape of a square, nest, or single seam.

Four-Loop, Four-Handle Big Bags

Four-handle Big Bags are primarily used in the construction, food, and pharmaceutical industries. Their key features include four lifting loops and various filling and discharge design options. The solid structure, high-quality materials, and flexibility of the four-loop Big Bag ensure maximum comfort for users and efficiency in storage and transport.

Q Big Bag

Q Big Bags help reduce transportation costs while ensuring maximum cargo safety. Thanks to their special design with internal partitions acting as stabilizers, they maintain a cubic shape during storage and transport. This feature enhances cargo security and optimizes the use of space inside the bags. Our Q Big Bags are equipped with four handles for convenient and easy handling.